How do you make leather cord earrings?

How Do You Make Leather Cord Earrings?

A Practical B2B Guide from Material to Market-Ready Product

Leather cord earrings are one of the most versatile jewelry products on today’s market. They combine natural texture with modern design, work across boho, minimalist, and luxury styles, and are loved for their lightweight comfort and strong visual impact. For designers, brands, and wholesale buyers, they represent a powerful product category that is easy to customize and scale.

But how exactly are leather cord earrings made and what matters most at a professional level?

In this guide, we walk through the full process: from choosing the right leather cords and components to design, assembly, quality control, and market positioning.

Why Leather Cord Earrings Are So Popular in the Jewelry Market

Leather cord earrings have grown in popularity for several important reasons:

-

They are lightweight and comfortable for all-day wear

-

They offer strong design flexibility — minimal, statement, or boho

-

They combine well with metal, gemstones, silk, and beads

-

They are suitable for both handmade collections and mass production

-

They align with the growing demand for natural and sustainable materials

For B2B buyers, leather cord earrings are attractive because they allow:

-

High perceived value with relatively low material cost

-

Easy seasonal color updates

-

Fast adaptation to fashion trends

-

Wide appeal across age groups and markets

Our collection of flat leather cords (small fraction)

Step 1: Choosing the Right Leather Cord

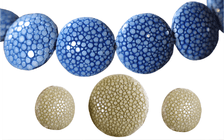

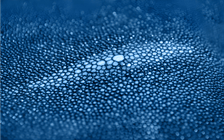

Everything starts with the leather cord itself. The quality of the cord determines not only the final look of the earring, but also its durability, flexibility, and comfort.

Key Factors to Consider:

-

Material type: Genuine leather vs bonded leather

-

Thickness: Usually between 1 mm and 3 mm for earrings

-

Finish: Matte, glossy, metallic, or suede-style

-

Color consistency: Essential for professional collections

-

Flexibility: The cord must bend without cracking

High-quality leather cords should feel soft but strong, with no chemical odor and no surface peeling.

At Sun Enterprises, leather cords are available in up to 1000 different colours and sizes, allowing brands to maintain precise color identity across collections and seasonal launches.

Step 2: Selecting the Earring Style

Before production begins, the design concept must be defined. Leather cord earrings can take many forms, including:

-

Minimal drop earrings – one straight leather cord with a metal top

-

Tassel earrings – multiple leather cords cut into equal lengths

-

Wrapped hoop earrings – leather cord wrapped around metal hoops

-

Geometric earrings – cords shaped into lines or abstract forms

-

Mixed-material designs – leather combined with silk, beads, or stones

From a B2B perspective, it is recommended to:

-

Develop 3–5 core designs for consistency

-

Add seasonal variations using color and charm updates

-

Maintain modular design logic for easier production scaling

Step 3: Cutting the Leather Cords

Precision cutting is essential for a professional finish.

Tools Commonly Used:

-

Sharp precision scissors

-

Rotary leather cutters

-

Industrial cutting machines (for large-scale B2B production)

Each earring must have:

-

Identical cord length

-

Clean, even edges

-

No surface tearing or fiber fraying

For tassel earrings, cords are typically cut between 3 cm and 7 cm, depending on design style. Precision at this stage directly affects product quality and visual balance.

Step 4: Attaching Clasps and Earring Findings

Once cords are cut, they must be securely attached to metal components. This is the structural core of the earring.

Common Components Used:

-

Earring hooks

-

Stud bases

-

Jump rings

-

Cord end caps

-

Crimp beads

The cord ends are inserted into metal caps and fixed using:

-

Professional jewelry glue

-

Mechanical crimping tools

For high-quality B2B production, stainless steel, gold-colored, or rose-gold components are preferred for:

-

Corrosion resistance

-

Skin safety

-

Higher perceived product value

At Sun Enterprises, matching clasps and jewelry components are available to ensure full material consistency across collections.

Step 5: Adding Decorative Elements

This is where design identity truly comes to life. Leather cord earrings can be enhanced using:

-

Metal charms

-

Gemstones

-

Wooden beads

-

Glass elements

-

Silk ribbons

Designers often combine leather cords with sari silk ribbons for a layered boho effect, or with minimal gold components for a clean, modern look.

From a commercial standpoint, decorative elements should be:

-

Easy to source consistently

-

Lightweight for wearing comfort

-

Securely attached to avoid product returns

Step 6: Closing, Polishing & Final Assembly

After all components are connected, each earring undergoes final finishing:

-

Jump rings are fully closed

-

Glue points are allowed to cure

-

Surface is cleaned from dust

-

Cords are aligned for symmetry

This stage may seem minor, but it is critical for:

-

Visual quality

-

Durability in shipping

-

Long-term customer satisfaction

Step 7: Quality Control for B2B Production

For wholesale and professional distribution, each batch must be checked for:

-

Identical color across pairs

-

Secure attachment points

-

Smooth leather surface

-

No glue overflow

-

Balanced weight between left and right earring

Quality control protects:

-

Brand reputation

-

Retail relationships

-

Long-term repeat orders

Step 8: Packaging & Branding

Presentation strongly influences perceived value. Leather cord earrings are often packaged in:

-

Recyclable kraft boxes

-

Logo-printed jewelry cards

-

Eco-friendly drawstring pouches

B2B buyers increasingly prefer sustainable packaging that matches the natural character of leather.

Why Leather Cord Earrings Are a Smart B2B Product Choice

From a business perspective, leather cord earrings offer several strategic advantages:

-

Low material waste during production

-

High design flexibility with minimal tooling

-

Easy color and style rotation

-

Strong demand in both online and offline retail

-

Alignment with eco and handmade trends

This makes them ideal for:

-

Jewelry brands

-

Fashion accessory wholesalers

-

Handmade product marketplaces

-

Concept stores and boutiques

Our collection of round leather cords (small fraction)

Complete Material Supply from Sun Enterprises

At Sun Enterprises, we support the full jewelry production process by supplying:

-

Leather cords in 1000+ colours and sizes

-

Silk cords and sari silk ribbons

-

Steel, gold, and rose-gold clasps

-

High-quality jewelry components

As a large B2B manufacturer, we help brands simplify sourcing, maintain consistent quality, and scale production confidently.

To inspire your next designs, explore our New Arrivals on our website:

www.sunenterprises.eu

From Handmade to High-Volume Production

One of the greatest strengths of leather cord earrings is that they can start as a handmade product and later be scaled into high-volume B2B production without losing their artisanal character. With the right materials, standardized cutting, consistent components, and controlled assembly, brands can grow quickly while maintaining quality.

Hope our blog was helpful for you and do not forget to follow our Instagram to learn even more useful information!