How is round leather cord made

How Round Leather Cord Is Made: From Raw Hide to Finished Material

Round leather cord is a fundamental material in many industries, from jewellery and fashion accessories to furniture, footwear, and leathercraft. Appreciated for its strength, flexibility, and natural appearance, it is widely used by designers and manufacturers who value durability and timeless aesthetics.

But how exactly is round leather cord made?

Behind every smooth, uniform leather cord lies a carefully controlled production process that transforms raw animal hide into a refined and versatile material. Understanding this process helps designers and buyers appreciate the quality differences between leather cords and make better material choices.

In this article, we’ll take a detailed look at how round leather cord is manufactured, step by step.

What Is Round Leather Cord Made Of?

Round leather cord is typically made from animal hides, most commonly:

- Cowhide

- Sheepskin

These hides are chosen for their balance of strength, flexibility, and durability. Cowhide is often preferred for thicker, more robust cords, while sheepskin is softer and more pliable, making it suitable for finer applications.

The quality of the final leather cord depends heavily on the quality of the raw hide and how carefully it is processed.

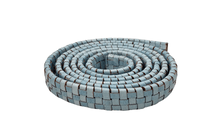

Our collection of round leather cords (small fraction)

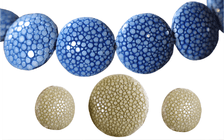

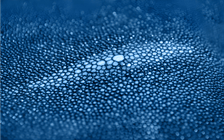

Step 1: Leather Selection

The production of round leather cord begins with selecting high-quality leather hides.

Manufacturers evaluate hides based on:

- Thickness

- Fiber density

- Flexibility

- Surface consistency

Only hides that meet strict standards are chosen, as imperfections at this stage can affect the strength and appearance of the finished cord.

Once selected, the hides undergo tanning, a crucial process that preserves the leather, prevents decay, and enhances durability. Tanning also determines how the leather will behave during cutting, shaping, and finishing.

Step 2: Cutting the Leather into Strips

After tanning, the leather hides are cut into long, narrow strips, often called thongs.

Key aspects of this step include:

- Cutting lengthwise along the hide

- Maintaining consistent width

- Ensuring smooth, even edges

Cutting lengthwise follows the natural grain of the leather, which improves strength and uniformity. Precision at this stage is essential, as inconsistencies can lead to weak points in the final cord.

Step 3: Skiving for Uniform Thickness

Skiving is the process of thinning the leather strips to achieve the desired thickness.

This step is critical because:

- Leather thickness affects flexibility

- Uniform thickness ensures a smooth, round shape

- It prevents weak or bulky sections

Skiving is typically done using specialized machines or tools that carefully shave the leather to precise measurements. The goal is to create strips that are even throughout their entire length.

Step 4: Stretching the Leather

Once skived, the leather strips may be stretched.

Stretching serves several purposes:

- Increases flexibility

- Improves consistency

- Helps prevent future shrinkage

This process can be done manually or mechanically, depending on production scale. Proper stretching ensures the leather cord will maintain its shape and performance during use.

Step 5: Rolling into a Round Shape

The defining step in creating round leather cord is rolling.

The flat leather strips are shaped into a cylindrical form by:

- Hand-rolling (in traditional or small-scale production)

- Machine-rolling (in modern manufacturing)

Rolling compresses the leather fibers inward, creating a smooth, round profile. Machinery allows manufacturers to achieve consistent diameter and surface quality across large quantities.

This step determines whether the cord will be:

- Perfectly round

- Even in density

- Comfortable to touch

Step 6: Polishing the Surface

After rolling, the leather cord often undergoes polishing.

Polishing:

- Smooths the surface

- Reduces roughness

- Enhances visual appeal

This process may involve:

- Abrasive rollers

- Polishing compounds

- Repeated rolling cycles

A well-polished leather cord feels soft, looks refined, and performs better in applications such as jewellery or furniture detailing.

Step 7: Dyeing and Finishing

Depending on the intended use, the round leather cord may then be dyed and finished.

Dyeing

Leather cords can be dyed in a wide range of colours using:

- Leather dyes

- Pigments

Dyeing can be:

- Surface-applied

- Drum-dyed for deeper colour penetration

The choice affects colour intensity and durability.

Finishing Treatments

After dyeing, the leather cord may be treated with:

- Wax

- Oils

- Protective finishes

These treatments:

- Enhance flexibility

- Improve resistance to wear

- Add subtle shine or matte effects

Finishing also helps protect the leather from drying out over time.

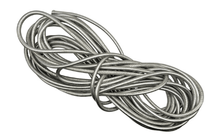

Step 8: Cutting to Length and Packaging

The final step is cutting the finished cord to length.

Round leather cords are typically:

- Cut into standard lengths

- Spooled onto rolls or reels

- Prepared for wholesale or retail sale

At this stage, quality control ensures:

- Consistent diameter

- Even colour

- Smooth surface

Only cords that meet specifications are packaged and distributed.

Different Types of Round Leather Cord

Not all round leather cords are the same. Variations in manufacturing can create different styles, including:

- Plain round leather cord – smooth, single-strand leather

- Braided round leather cord – multiple strands braided together

- Stitched leather cord – sewn for added structure

Each type may require additional steps or specialized techniques to achieve its final texture and appearance.

Why Manufacturing Quality Matters

The way round leather cord is made directly impacts:

- Strength

- Flexibility

- Appearance

- Longevity

High-quality production ensures cords that:

- Do not crack easily

- Maintain shape over time

- Feel comfortable to touch

This is especially important for applications like jewellery, furniture, and accessories where performance and aesthetics matter equally.

Applications of Round Leather Cord

Thanks to this detailed manufacturing process, round leather cords are used in:

- Jewellery making

- Bracelets and necklaces

- Furniture design

- Footwear and shoelaces

- Leathercraft projects

Their versatility is a direct result of the careful steps involved in their production.

Conclusion

Round leather cord may appear simple, but its creation is a refined process that combines tradition, precision, and craftsmanship. From selecting premium hides to rolling, polishing, and finishing, every step contributes to the quality of the final product.

Understanding how round leather cord is made helps designers and manufacturers choose better materials and create products that last.

When produced correctly, round leather cord remains one of the most reliable and elegant materials available for both functional and decorative use.